Hi there,

So you just spent a few weeks on a critical simulation. You feel confident about all of the inputs, the mesh "looks good" (whatever that means), the numerical setup aligns with industry best practices and recommended workflows from the CAE help files, and there were no errors during the solve. The results must be right ... right?

Building trust in your simulation results can only come after you correlate those results to your empirical test data. However, the dirty little secret in the world of CAE, is that not nearly as many companies do this as you might think. In the fast-paced, cost-conscience world of manufacturing, engineering support is too often yanked off the project as soon as the design passes its tests. It's a crime.

Want to fix that? For those looking for a standardized methodology to increase the quality of their analyses, the American Society of Mechanical Engineers have published a Verification and Validation Guideline for use with both Computational Solid Mechanics as well as Computational Fluid Dynamics and Heat Transfer. It's the CAE industry standard guidelines for removing error from your process, and building trust in your simulations.

But fair warning - you'll have to change your current culture to implement it. Not ready to make waves in your organization by deploying a formal V&V process? That's okay. In the mean time, here are some quick tips and tricks that we've learned over the years that can help you gain confidence in your results, even if test data is questionable, incomplete, or non existent altogether.

Material Sensitivity Analyses

In a commercial setting, many designers rely on the internet to provide their material property sources from places like Matweb.com. There may not be much risk in this if you are designing a CNC machined steel component to never yield, but if you are trying to predict crack growth in die cast aluminum, the internet only provides a sense of false confidence.

One way to gain confidence in your results, is to try a few different values for the Elastic Modulus and Poisson's Ratio. If small changes in these values result in insignificant changes in your stresses, then the model is not that sensitive to the material properties. In these case the risk of moving forward can be small. But, if small changes in material properties show large swings in deflection/strain/stress, then the risk of moving forward is high, and the cost of getting your own material test done may be worth it.

Mesh Independence Study

The world is made of a mesh at the atomic level (at least that's what we learned in school). However, we are quite a ways away from being able to simulate our components and assemblies at that level of detail. So, in the mean time we will continue to create an overly coarse mesh in our simulation so it can be solved. Every single student in our class asks, "Whats the best mesh size?". Often our response is, "I don't know." The real answer is, "the coarsest possible mesh, that still correlates to test data," so we can get answers at the speed of business. But when is coarse too coarse? Well, for that answer we need to do a mesh study.

The typical way to do this is to start with a relatively coarse mesh (for example, several elements through the thickness for structural FEA) that is still tight enough to capture our geometry and capture the load path. Solve it. Look for areas of high stress (FEA) or velocity (CFD) gradients. Locally increase the mesh density. Solve it again. Repeat until the stress/velocity stop changing.

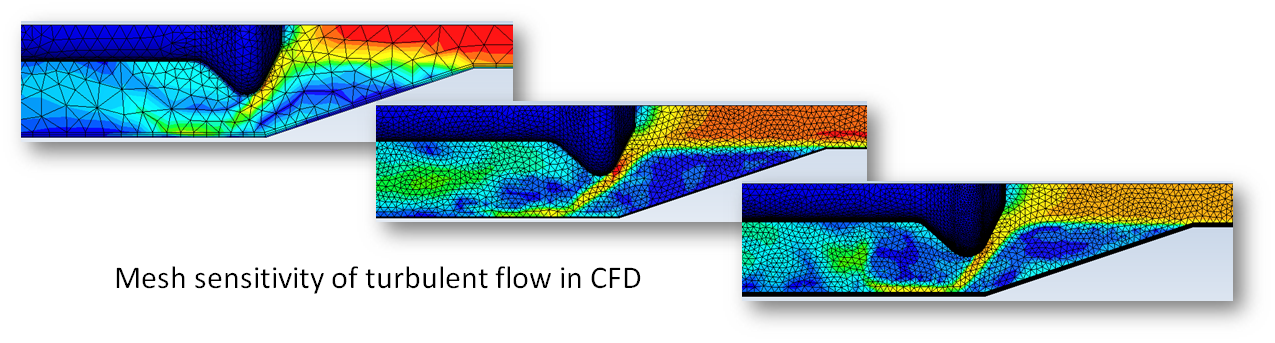

This is, of coarse, just the beginning of creating a high quality mesh, but it is still overlooked far too often. Bottom line? Use your results to help guide you where to add mesh refinements, such as in this mesh sensitivity study from our Intro to CFD class shown below:

Thorough Documentation

When in doubt, document everything you do. A properly written CAE report should include a quick Intro/History, Methodology & Assumptions, CAD geometry preparation, any bespoke numerical setup details (solver settings), Results & Discussion, and Conclusion with recommended next steps. If the enough information for the reader to repeat the analysis. It's not necessary to detail all of the "picks and click" involved in using the software, as the actual CAE files should be backed up, so it can be picked up and resolved.

Believe it or not, a lot of our clients come to us after they have had some FEA or CFD done. They say, "We had this done by another outside engineering firm, but we don't think we trust the results." When we ask them why, the #1 Reason is because the report was not thorough enough. Precision instills trust - both in your own abilities, and in the eyes of your Customer/Manager, etc. Be precise with your process, and thorough with your documentation of it.